Linea productionis automatica ampullarum quadratarum 10-20L

Linea productionis automatica ampullarum quadratarum 10-20L

Proprietates Praecipuae

1. Plus quam viginti annos experientiae et famae et domi et foris;

2. Qualitatis Cura, praeclara post-servitia et pretium rationabile;

3. Fidele et tutum ad regendum, facile ad operandum et conservandum;

4. Interfacie humana-computatrali et PLC instructum; technologiam moderationis digitalis adoptatur;

5. Plena automatica, semi-automatica, et multiforma, apta diversis formis et magnitudinibus vasculorum.

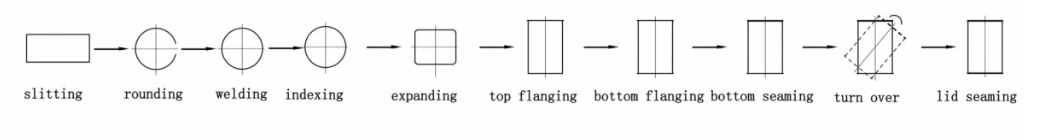

Processus operandi lineae productionis automaticae magnae vasis quadrati

Primum, materias corporis pyxidis incisas in mensam alimentationis machinae automaticae ad resistentiam soldandam pone. Per suctores vacui suge, et singula stanna ad cylindrum alimentatorium mitte. Per cylindrum alimentatorium, singula stanna ad cylindrum rotundationis immittitur ad processum rotundationis peragendum, deinde ad mechanismum formationis rotundationis immittetur ad rotundationem faciendam.

Corpus in machinam ferrariam resistentiae immittitur et, post positionem accuratam, ferrulam perficitur. Post ferrulam, corpus pyxidis automatice in convectorem magneticum rotatorium machinae liniendi immittitur, sive exteriorem sive interiorem, sive interiorem pulveris obliniendi causa, quod ex variis necessitatibus emptoris pendet. Praecipue adhibetur ne linea suturae lateralis aere pateat et rubigo fiat. Corpus pyxidis, sive exteriorem sive interiorem pulveris obliniendum est, in furnum siccatorium inductionis ponendum est ad siccandum. Post siccationem, ad instrumentum refrigerandi immittetur, ut refrigeratio naturalis fiat.

Corpus vasis refrigeratum deinde ad machinam magnam quadratam compositam immittitur, et corpus vasis erectum est, per convectorem erectionis transiens. Ad primam stationem automaticam suturarum lateralium indicandarum per forcipes immittitur. Secunda statio quadrata expansio est. Cum corpus vasis in loco est, in alveo elevatorio corporis vasis, qui a servomotore regitur, corpus vasis per hoc alveum elevatorium ad formam quadratam expansionis mittitur, ut expansionem quadratam efficiat. Tertia statio tabulas et angulos in eminentia efficit.

Cum corpus pyxidis in situ est, in alveo elevatorio corporis pyxidis, quod a motore servo regitur, corpus pyxidis ab hoc alveo elevatorio ad tabulam fabricationis et embossuras angulares simul transmittitur. Quarta statio est flangatio superior, quinta statio est flangatio inferior. Flangatio inferior: pyxis ad formam flangationis inferioris in parte superiore machinae iacentem, alveo elevatorio, mittetur ad eam faciendam. Flangatio superior: cylindrus superior corpus pyxidis ad positionem formae flangationis superioris premet ad eam faciendam.

Flanges corporis vasis, tam superior quam inferior, quattuor cylindris aguntur. Sexta statio operculi automatice detegit, alimentat, et suturam facit. Post sex supradicta, vas sursum deorsumque invertetur instrumento reversivo, deinde sutura superior fit; hic processus idem est ac processus suturae inferioris. Denique, vas perfectum a convectore ad stationem automaticam probationis effluxionum transmittitur. Post accuratam inspectionem fontis aeris, producta non qualificata deteguntur et ad locum fixum impelluntur, et producta qualificata ad mensam involucri pro processu finali involucri venient.

Partes constituentes huius lineae fabricationis vasorum metallicorum

| Prima incisio/latitudo minima | 150mm | Secunda incisio/latitudo minima | 60mm |

| Celeritas /pcs/min | 32 | Crassitudo laminae | 0.12-0.5mm |

| Potestas | 22 kW | Tensio electrica | 220V 380V 440V |

| Pondus | 21100kg | Dimensio Machinae | 2530X1850X3990mm |

In linea productionis typica corporum metallicorum, machina secandi est primum stadium processus fabricationis. Laminas metallicas impressas et laccatas in corpus brutum magnitudinis requisitae secat. Additio unitatis translationis acervi bruti efficientiam machinae secandi ulterius auget.

Nostrae machinae secandae ad mensuram factae sunt. Valde robustae sunt, facilem celeremque adaptationem ad varias formas materiae vacuae faciliorem reddunt, et praecisionem altissimam praestant. Cum ad versatilitatem, praecisionem, firmitatem et celeritatem productionis attinet, nostrae machinae secandae ad productionem corporum stanneorum aptissimae sunt.

| Exemplar machinae | CTPC-2 | Tensio et Frequentia | 380V 3L+1N+PE |

| Celeritas | 5-60m/min | Consumptio pulveris | 8-10mm et 10-20mm |

| Consumptio aeris | 0.6Mpa | Diametri vasis | D50-200mm D80-400mm |

| Aeris requisitum | 100-200L/min | Consumptio energiae | 2.8 kW |

| Dimensiones | 1090*730*1830mm | Pondus | 310 chiliogrammata |

Systema pulveris applicandi unum ex productis pulveris applicandi a societate Changtai productis est. Haec machina technologiae pulveris applicandi suturas cisternarum fabricatorum vasorum destinata est. Societas nostra technologiam pulveris applicandi provectam adhibet, quae structuram machinae novam, systematis magnam firmitatem, operationem facilem, latam applicationem, et rationem pretii altam praebet. Usus autem elementorum moderandi fidorum, terminalium tactilium aliorumque elementorum systema stabilius et fidius reddit.

| Frequentiae amplitudo | 100-280Hz | Celeritas soldadurae | 8-15m/min |

| Facultas productionis | 25-35 ampullae/min | Diameter vasis applicabilis | Φ220-Φ300mm |

| Altitudo vasis applicabilis | 220-500mm | Materia applicabilis | Lamina stannea, chalybea, lamina chromata |

| Crassitudo materiae applicabilis | 0.2~0.4mm | Diameter fili aenei applicabilis | Φ1.8mm, Φ1.5mm |

| Aqua refrigerans | Temperatura: 12-20℃; Pressio: >0.4Mpa; Fluxus: 40L/min. | ||

| Potentia totalis | 125KVA | Dimensio | 2200*1520*1980mm |

| Pondus | 2500 kg | Pulvis | 380V ± 5% 50Hz |

Machina ad corpora ferraria instar cannarum metallicarum (vel "vasorum metallicorum") cor cuiusvis lineae productionis vasorum metallicorum trium partium constituit. Formas corporis in formam fundamentalem format et suturas superpositas conglutinat. Nostrum principium ferrariae Superwima tantum minimam superpositionem paucarum decimorum millimetri requirit. Optima gubernatio currentis ferrariae cum pressione accurate aptata in superpositione coniungitur. Ex quo nova generatio machinarum ferrariarum emissa est, clientes toto orbe hodie magnam satisfactionem de eximia et alta firmitate machinae, una cum productione oeconomica et efficaci, confirmaverunt. Nova norma industrialis in fabricatione corporum ferrariorum toto orbe constituta est.

| Altitudo vasis applicabilis | 50-600mm | Diameter vasis applicabilis | 52-400mm |

| Celeritas cylindri | 5-30m/min | Genus tegumenti | Obductio cylindri |

| Latitudo laccae | 8-15mm 10-20mm | Copia principalis et onus currentis | 220V 0.5 kW |

| Consumptio aeris | 0.6Mpa 20L/min | Dimensiones machinae | 2100*720*1520MM 300kg |

Machina pulveris liniendi pars magni momenti est lineae productionis trium partium vasorum, quae a clientibus domi et externis in foro magnis laudibus accipitur et instrumentum excellens ad vasos faciendos praebet. Chengdu Changtai operam dat ut clientibus instrumenta optimae qualitatis ad vasos faciendos praebeat et optimam solutionem evolvat.

| Celeritas convectoris | 5-30m/min | Diametri vasis | 52-180mm |

| Typus convectoris | Transmissio catenae planae | Serpentina ductus refrigerantis | Aquam/aerem non requirit |

| Calefactio efficax | 800mm*6 (30cpm) | Copia principalis | 380V+N > 10KVA |

| Genus calefactionis | Inductio | Distantia sentiendi | 5-20MM |

| Calefactio Superior | 1KW*6 (temperatura constituta) | Punctum inductionis | 40MM |

| Frequentiae constitutio | 80KHz +-10KHz | Tempus inductionis | 25 secunda (410 mm altitudo, 40 cpm) |

| Protectio electroradiationis | Tectum praesidiis salutis | Tempus ascensionis (MAX) | Distantia 5mm 6sec et 280℃ |

| Demensio | 6300*700*1420mm | Pondus Nettum | 850 kg |

Changtai seriem modularem systematum curationis habet, quae stratum suturarum protectivum efficaciter durescere designata sunt. Statim post applicationem strati laccati vel pulveris suturarum protectivi, corpus vasis tractatione caloris subit. Systemata calefactionis modularia provecta, gas vel inductione operata, cum regulatione temperaturae automatica et taeniis transportatoriis celeritate adaptabilibus elaboravimus. Utraque systemata calefactionis in dispositione lineari vel forma U praesto sunt.

Machina automatica combinationis corporum vasis metallici

| Capacitas productionis | 30-35 cpm | Diametri amplum vasis | 110-190mm |

| Altitudo vasis amplus | 110-350mm | Crassitudo | ≤0.4 |

| Potentia totalis | 26.14kW | Pressio systematis pneumatici: | 0.3-0.5Mpa |

| Magnitudo convectoris corporis erectionis | 2350*240*930mm | Magnitudo convectoris alimentationis | 1580*260*920mm |

| Magnitudo machinae combinatae | 2110*1510*2350mm | Pondus | 4T |

| Magnitudo armarii electrici | 710*460*1800mm | ||

Linea productionis vasculorum metallicorum plerumque palletizatore terminatur. Linea sitularum congregandarum aptari potest, quod acervos qui in gradibus proximis palletizari possunt praestabit.

Linea productionis automaticae vasculorum rotundorum

Linea productionis ad amphoras fabricandas apta est ad productionem automaticam amphorarum quadratarum 10-20L, quae ex tribus laminis metallicis constat: corpore, operculo, et fundo. Amphora formam quadratam habet.

Fluxus technicus: secans laminam stanneam ad vacuam - rotundatio - soldadura - involucrum interius et externum

(involucrum pulveris interior et involucrum exterior) - exsiccatio - refrigeratio - vectura - tabula quadrata expansionis

embossura anguli - flangatio superior - flangatio inferior - alimentatio operculi inferioris - sutura - versatio -

Alimentatio operculi superioris - sutura - probatio effusionis - involucrum