Linea productionis automatica doliorum magnorum 30-50L, tympanorum, sitularum, et corporum cistularum

Linea productionis automatica doliorum magnorum 30-50L, tympanorum, sitularum, et corporum cistularum

Linea productionis automaticae vasculorum rotundorum

Aptus ad productionem automaticam doliorum magnorum 30-50L,

Tres laminae metallicae:corpus vasis, operculum vasis et fundum vasis.Vasculum estcylindricusforma.

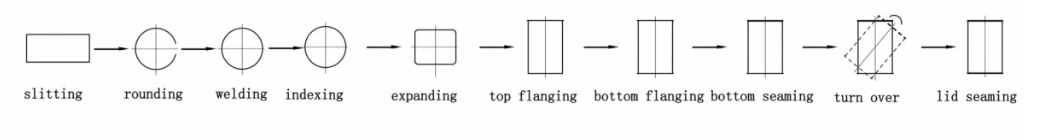

Fluxus technicus:

secans laminam stanneam ad rotunditatem vacuam (Sectio)-Soldatura-externusTegumentum-Flangens-operculum inferiuspascens-Sutura-Vertenssupra-Toperculum apertumpascens-Sutura-+Orla aurissoldatioExaminatio effusionis - involucrum

Linea productionis doliorum faciendorum praesto est.Hic preme ut informationes singulas accipias.

Quomodo haec linea productionis doliorum operanda est?

Primum materiam corporis pyxidis sectam in mensam alimentatricem machinae automaticae ad resistentiam soldandam pone, per aspiratores vacui suge, deinde singula stanna ad cylindrum alimentatorem mitte. Per cylindrum alimentatorem, singula stanna ad cylindrum rotundationis immittitur ad processum rotundationis peragendum, deinde ad mechanismum rotundationis formandi immittetur ad rotundationem faciendam. Corpus in machinam resistentiae soldandam immittitur et post accuratam positionem soldadura fit.

Post soldaduram, corpus pyxidis automatice in convectorem magneticum rotatorium machinae obductionis immittitur, sive ad obductionem exteriorem, sive ad obductionem interiorem pulveris, quod ex variis necessitatibus emptoris pendet. Praecipue adhibetur ne linea suturae lateralis soldadurae in aere pateat et rubiginem formet. Corpus pyxidis deinde ad machinam compositam immittitur, statu erecto per convectorem erectionis transiens, et ad stationem flangendi per fibulas mittitur. Opus flangendi perficitur per impulsionem formae flangendi superioris et inferioris.

Post hoc, corpus vasis cum flangibus ad alimentatorem automaticum operculi inferioris mittitur; per sensorem detectorem corpus vasis advenientem detegens, alimentator operculi operculum inferius automatice ad summum corporis vasis mittet, et ambo ad locum sub frusto suturae mittuntur; alveus elevans corpus vasis et fundum ad caput machinae suturae mittit ut sigillentur.

Post suturam unius extremitatis, ad versorem corporis vasis mittitur, ut corpus vasis invertatur, deinde iterum operculum superius automatice detegat et suturam facit. Denique ad machinam automaticam duplicis puncti pro fibulis auricularibus adglutinandis transmittitur, quae per indicationem automaticam suturarum lateralium, translationem per cammam, frangendum mechanicum pigmenti, etiam instructa discos vibrantes automaticos fibulorum auricularium, opus accurate suturandi in parva vase rotundo perficit.

Denique, vas perfectum per ferrum ad stationem automaticam ad effluxiones probandas transmittitur. Post accuratam inspectionem fontis aeris, producta non qualificata deteguntur et ad locum fixum impelluntur, et producta qualificata ad mensam involucrorum pro involucro finali venient.

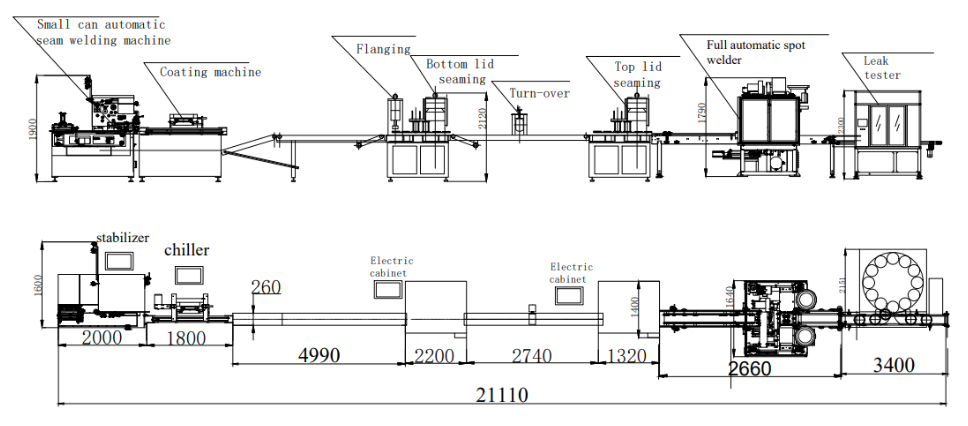

Compositio instrumentorum lineae productionis automaticae pro vasis rotundis

| Prima incisio (latitudo minima) | 150mm | Secunda incisio (latitudo minima) | 60mm |

| Celeritas (unc./min.) | 32 | Crassitudo laminae | 0.12-0.5mm |

| Potestas | 22kW | Tensio electrica | 220V/380V/440V |

| Pondus | 21000kg | Dimensiones (L*L*A) | 2520X1840X3980mm |

| Modellum | CTPC-2 | Tensio et Frequentia | 380V 3L+1N+PE |

| Celeritas productionis | 5-60m/min | Consumptio pulveris | 8-10mm et 10-20mm |

| Consumptio aeris | 0.6Mpa | Spatium corporis can | D50-200mm D80-400mm |

| Aeris requisitum | 100-200L/min | Consumptio energiae | 2.8 kW |

| Dimensio machinae | 1080*720*1820mm | Pondus grossum | Trecenti chiliogrammata |

| Frequentiae amplitudo | 100-280Hz | Celeritas soldadurae | 6-15m/min |

| Facultas productionis | 15-35 ampullae/min | Diameter vasis applicabilis | Φ220-Φ350mm |

| Altitudo vasis applicabilis | 220-550mm | Materia applicabilis | Lamina stannea, chalybea, lamina chromata |

| Crassitudo materiae applicabilis | 0.2~0.6mm | Diameter fili aenei applicabilis | Φ1.7mm, Φ1.5mm |

| Aqua refrigerans | Temperatura: 12-20℃; Pressio: >0.4Mpa; Fluxus: 40L/min. | ||

| Potentia totalis | 125KVA | Dimensio | 2200*1520*1980mm |

| Pondus | 2500 kg | Pulvis | 380V ± 5% 50Hz |

| Potentia ignis | 1-2 kW | Celeritas calefactionis ignitoris | 4m-7m/min |

| Diametro parvo apto vasis | Φ45-Φ176mm | Diametro amplo vasis apto | Φ176-Φ350mm |

| Altitudo vasis | 45mm-600mm | Aqua refrigerans | >0.4Mpa, 12-20℃, 40L/min |

| Consumptio aeris | ≥50L/min >0.5Mpa | ||

Machina automatica combinationis corporum vasis metallici

| Capacitas productionis | 25-30 cpm | Diametri amplum vasis | 200-300mm |

| Altitudo vasis amplus | 170-460mm | crassitudo | ≤0.4mm |

| Potentia totalis | 44.41 kW | Pressio systematis pneumatici | 0.3-0.5Mpa |

| Magnitudo convectoris corporis erectionis | 4260*340*1000mm | Magnitudo machinae combinatae | 3800*1770*3200mm |

| Magnitudo armarii electrici | 700*450*1700mm | Pondus | 9T |

Sinarum praebitor princepsMachina trium partium ad vascula stannea faciendaetMachina Fabricandi Vasa AerosolicaChangtai Intelligent Equipment Co., Ltd. est officina perita machinarum in vasis metallicis faciendis. Systemata nostra, inter quae sunt separatio, formatio, colligatio, flangiatio, marginatio et sutura, modularitatem et facultatem processus altissimam praebent et ad amplam applicationum varietatem apta sunt. Celeri et simplici adaptatione, productivitatem altissimam cum optima qualitate producti coniungunt, simul altum gradum salutis et efficax tutelam operatoribus offerunt.