processus productionis principalis pro corpore vasis cibariis trium partium

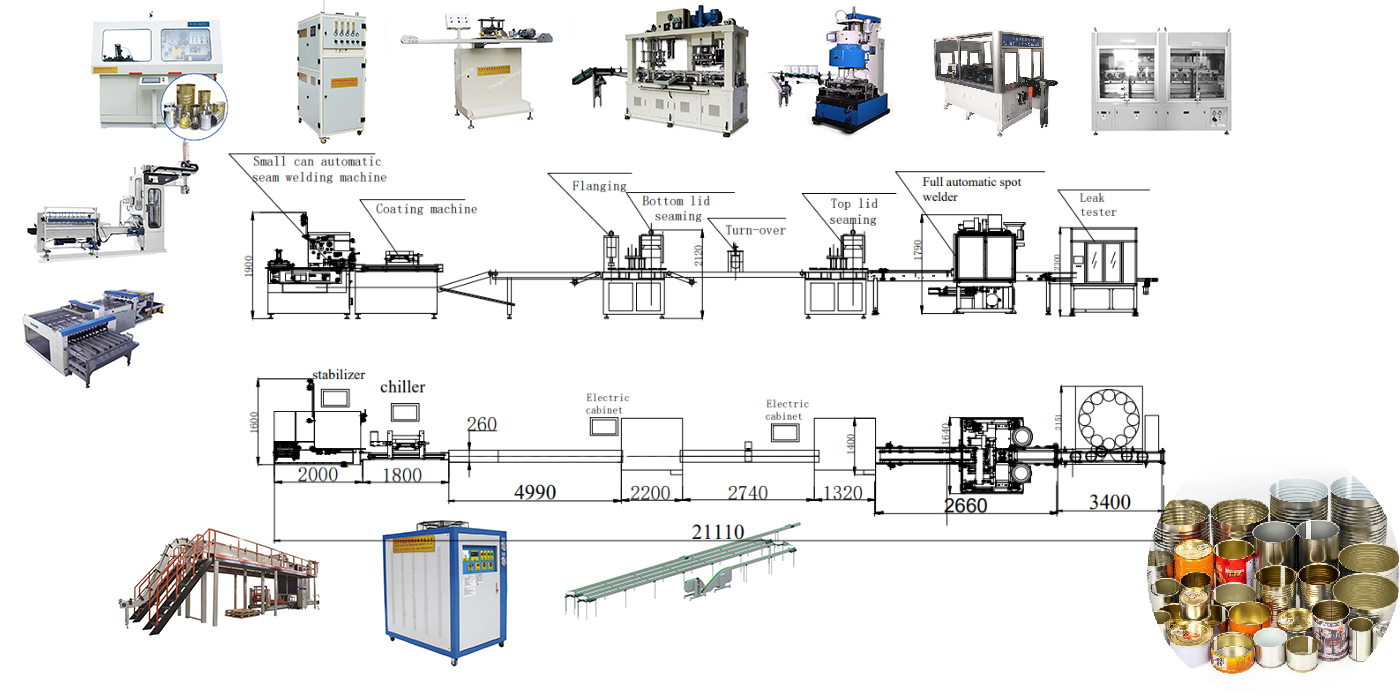

Processus productionis principalis corporis vasis cibariorum trium partium comprehenditsecans, ferruminatio, obductioetexsiccatiosuturae, colligationis, flangendi, marginationis, obsignationis, probationis effusionis, pulverisationis et siccationis plenae, et involucri. In Sinis, linea automatica productionis vasorum metallicorum typice constat ex machinis corporum componendi, machinis bidirectionalibus ad tondendum, machinis ad soldaduram, systematibus tutelae suturae et obductionis/curationis, systematibus pulverisationis/curationis interioris (ad libitum), machinis detectionis effusionis in linea, machinis ad congerendum vasos metallicos vacuos, machinis ad fascias ligandas, et machinis ad involvendum pelliculam/contrahendum calore. Hodie, machina corporum componendi processus perficere potest ut scindere, colligationem, expansionem, dilatationem vasorum metallicorum, flangendi, marginationis, primam et secundam suturationem, celeritate usque ad 1200 vasos metallicos per minutum. In articulo priori, processum scindendi explicavimus; nunc, processum colligationis analyzemus:

Cervicem

Una methodus magni momenti ad consumptionem materiae minuendam est per attenuationem laminae stanneae. Fabricatores laminae stanneae magnum opus in hac re perfecerunt, sed simpliciter attenuatio laminae stanneae ad sumptum vasis reducendum limitatur a requisitis resistentiae pressionis structurae vasis, et eius potentia nunc satis parva est. Attamen, cum progressibus in technologia colligationis, flangeationis, et expansionis vasis, novae inventiones in consumptione materiae minuenda factae sunt, praesertim et in corpore vasis et in operculo.

Primaria causa productionis pyxidum collo instructarum initio orta est desiderio fabricatorum producta emendandi. Postea inventum est coagulationem corporis pyxidis efficax esse modum materiae conservandae. Coagulatio diametrum operculi minuit, ita magnitudinem partis obturantis minuens. Simul, cum robur operculi cum diametro reducto crescit, materiae tenuiores eandem efficaciam consequi possunt. Praeterea, vis imminuta in operculo aream obturandi minorem permittit, magnitudinem partis obturantis ulterius minuens. Attamen, tenuatio materiae corporis pyxidis problemata ob mutationes in tensione materiae, ut resistentiam imminutam secundum axem pyxidis et sectionem transversalem corporis pyxidis, causare potest. Hoc periculum auget durante processibus impletionis altae pressionis et transportatione a impletoribus et venditoribus. Ergo, dum coagulatio materiam corporis pyxidis non significanter minuit, materiam in operculo praecipue conservat.

Ob horum factorum vim et postulationem mercatus, multi fabri technologiam colli imponendi emendaverunt et provexerunt, sibi locum singularem in variis gradibus fabricationis vasculorum stabilientes.

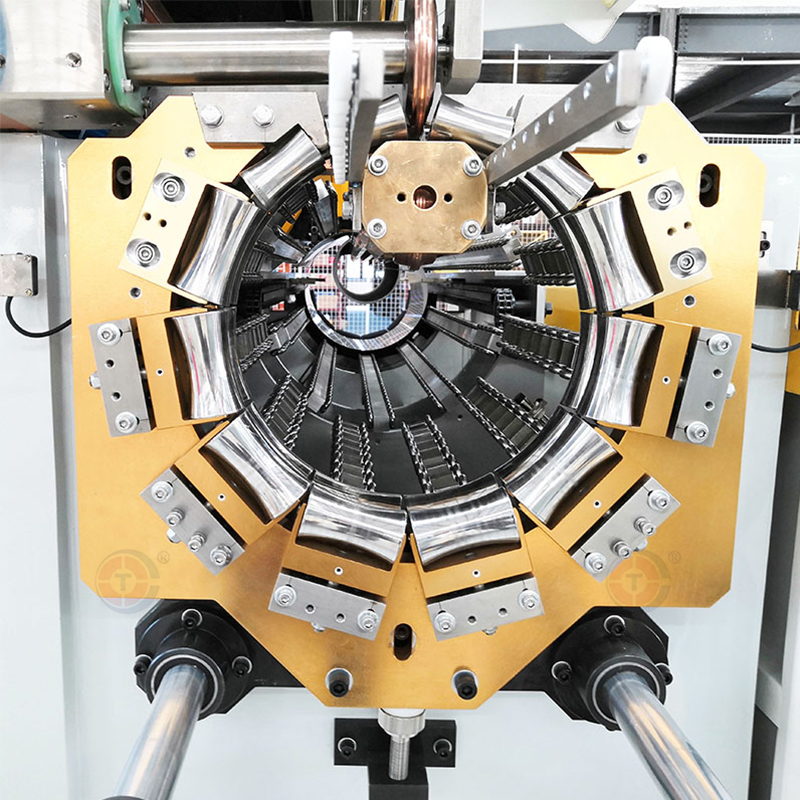

Absente processu scindendi, primus processus est "collage". Post obductionem et curationem, corpus vasis successive ad stationem collage per vermem separationis vasis et rotam stellarem immittendam defertur. Ad punctum translationis, forma interna, camma gubernata, axialiter in corpus vasis movetur dum rotatur, et forma externa, etiam camma ducta, inseritur donec formae internae congruat, processum collage perficiens. Deinde forma externa primum dissolvitur, et corpus vasis in forma interna manet ne labatur donec punctum translationis attingat, ubi a forma interna dissolvitur et per rotam stellarem immittetur ad processum flangationis. Typice, methodi et symmetricae et asymmetricae colligationis adhibentur: prior ad pyxidem 202 diametro applicatur, ubi ambo extremitates colligationem symmetricam subeunt ut diameter ad 200 reducatur. Posterior unum extremum pyxidis 202 diametro ad 200 et alterum extremum ad 113 reducere potest, dum pyxis 211 diametro ad 209 et 206 respective post tres operationes colligationis asymmetricae reduci potest.

Tres principales technologiae colligationis sunt

- Strictio formaeDiameter corporis vasis metallici uno vel utroque extremo simul contrahi potest. Diameter ad unum extremum anuli colli aequalis est diametro originali corporis vasis metallici, alter autem extremum diametro colli ideali aequalis est. Dum operatur, anulus colli secundum axem corporis vasis metallici movetur, et forma interna rugas impedit dum collimationem accuratam curat. Quaeque statio limitem habet quantum diameter reduci potest, secundum qualitatem materiae, crassitudinem, et diametrum vasis metallici. Quaeque reductio diametrum circiter 3mm diminuere potest, et processus collimationis multi-stationis eum 8mm reducere potest. Dissimilia vasis metallicis bipartitis, vasis metallicis trium partium non aptae sunt ad collimationem formae repetitam propter incongruentiam materiae in sutura.

- Strinctionem sequentem aciculaeHaec technologia a principiis colligationis vasculorum bipartitorum derivatur. Curvas geometricas lenes permittit et colligationem multi-gradualem accommodare potest. Magnitudo colligationis 13mm attingere potest, pro materia et diametro vasculi. Processus inter formam internam rotantem et formam externam formatricem fit, numero rotationum pro magnitudine colligationis pendente. Forcipes altae praecisionis concentricitatem et transmissionem vis radialis curant, deformationem prohibentes. Hic processus curvas geometricas bonas cum minima iactura materiae producit.

- Formatio formaeContra formae colli formandi, corpus pyxidis ad diametrum desideratam expanditur, et forma formans ab utroque extremo intrat, curvam colli finalem formans. Hoc processu uno gradu superficies leves efficere potest, qualitate materiae et integritate suturae differentiam in forma colli determinantibus, quae usque ad 10 mm pervenire potest. Formatio idealis crassitudinem laminae stannae 5% minuit, sed crassitudinem ad collum retinet, dum robur generale auget.

Hae tres technologiae colligationis singulae commoda offerunt secundum requisita specifica processus fabricationis vasculorum.

Video Connexa Machinae Soldandi Stannei Canis

Chengdu Changtai Intelligent Equipment Co., Ltd. - Fabricator et Exportator apparatus automatici ad vasa stagnea fabricanda, omnes solutiones ad vasa stagnea fabricanda praebet. Ut nuntios novissimos de industria involucrorum metallicorum cognoscas, novam lineam productionis ad vasa stagnea fabricanda inveni, et pretia de machinis ad vasa stagnea fabricanda accipias, machinam qualitate praestantem ad vasa stagnea fabricanda apud Changtai elige.

Contacta nosde machinis singulis:

Telephonum: +86 138 0801 1206

Whatsapp: +86 138 0801 1206 +86 134 0853 6218

Email:neo@ctcanmachine.com CEO@ctcanmachine.com

Tempus publicationis: Oct-XVII-MMXXIV